The challenge

In today’s automotive industry, a growing concern among vehicle manufacturers centers on the issue of low-frequency noise and booming effects within passenger cabins, a focal point that gains prominence, especially in case of electric vehicles. Even the most high-end cars exhibit a low-frequency rumble when navigating obstacles or traversing uneven roads.

This distinctive noise, characterized by its deep pitch and pulsating nature, presents a potential source of discomfort and fatigue for passengers. Consequently, this dynamic opens up promising research opportunities for experts in acoustics within the automotive industry.

To address this phenomenon, creating a controlled environment that mirrors real-world vehicle conditions becomes imperative. This involves meticulous control over factors such as road surfaces and driving conditions within a stable setting. The integration of advanced equipment capable of measuring both sound and vibrations is crucial for facilitating comprehensive studies.

The adopted approach entails a thorough exploration of the vibrational and acoustic responses of a car, offering valuable insights into mitigating the impact of low-frequency noise in passenger cabins.

The solution

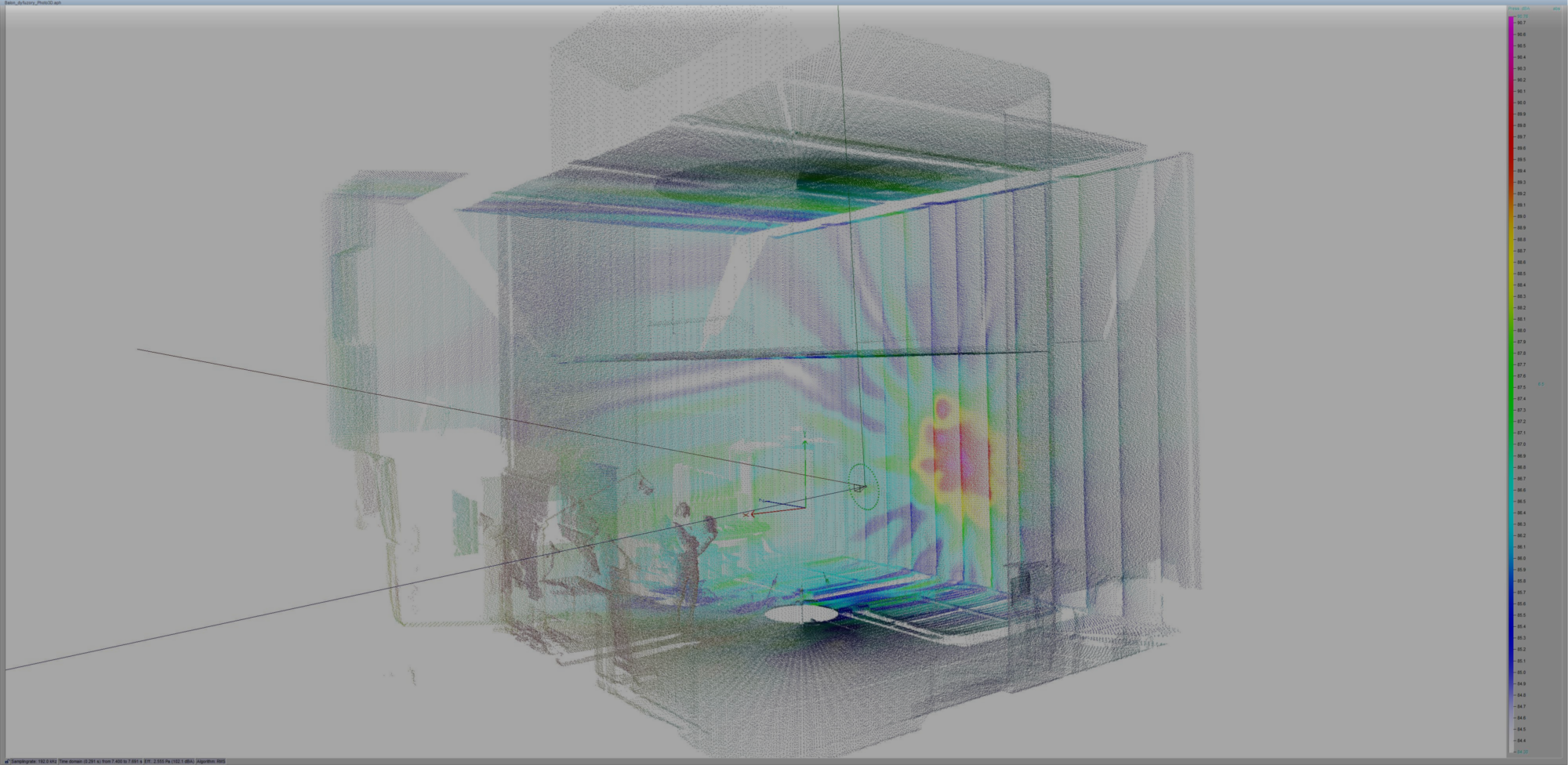

The methodology for investigating the aforementioned phenomenon was created by KFB Acoustics in the Acoustic Research and Innovation Centre (ARIC) in Poland. This specialised test stand integrates an acoustic dynamometer with a 3D laser Doppler vibrometer, which is operated by a scanning robot. Housed within a semi-anechoic chamber, the system is fully equipped with a comprehensive sound and vibration acquisition setup.

The synergy between the Semi-anechoic Dynamometer facility and the cutting-edge 3D laser vibrometer provides a powerful toolkit for conducting in-depth NVH (Noise, Vibration, and Harshness) analyses. It allows discerning sources, characterising structural dynamics, and formulate targeted solutions aimed at optimizing vehicle comfort while mitigating noise and vibrations.

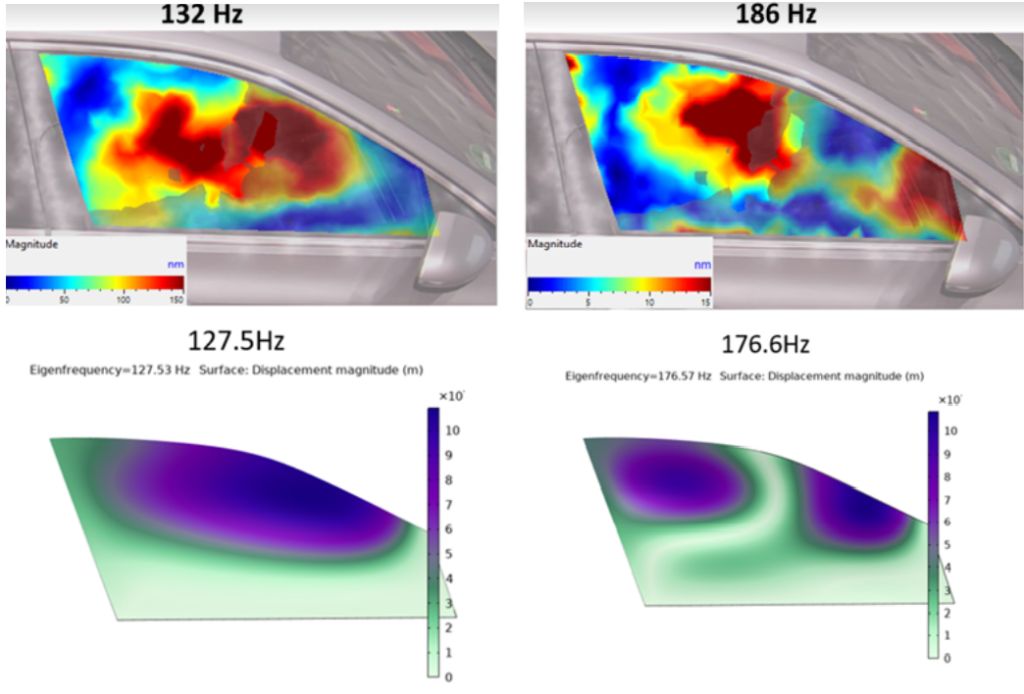

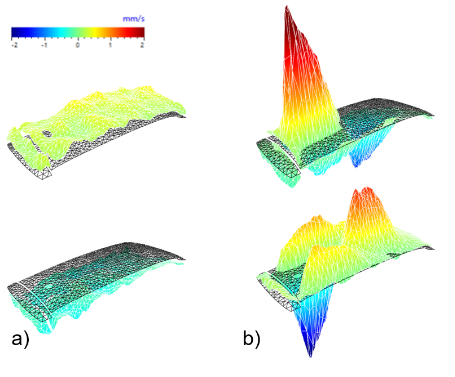

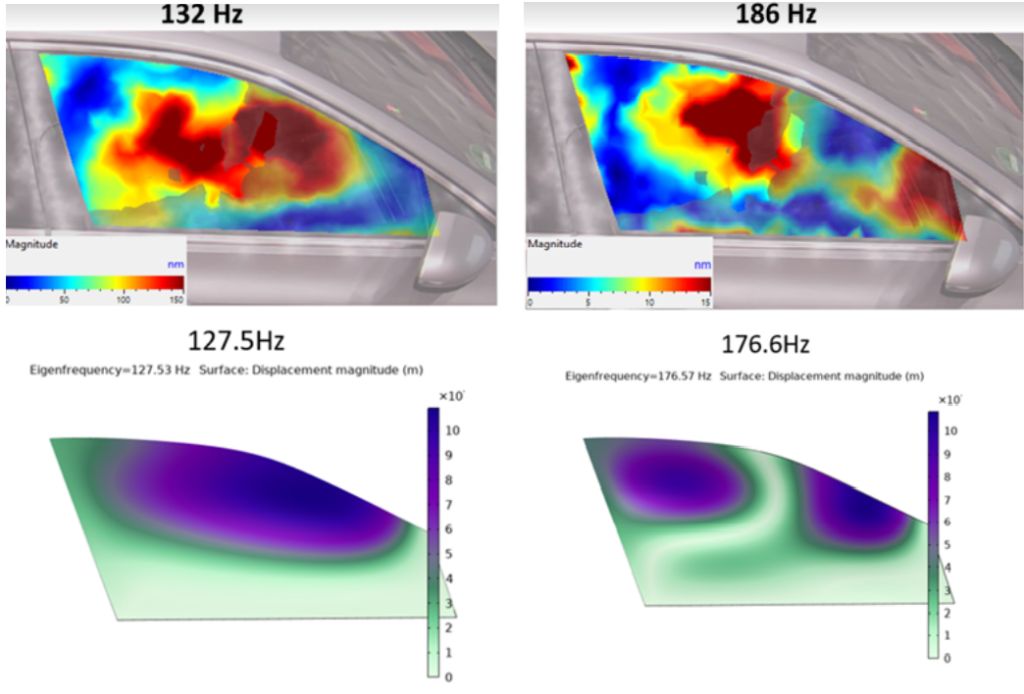

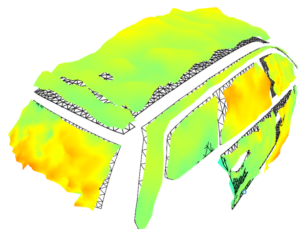

Upon acquiring experimental data, researchers utilize recorded noise and vibration measurements to refine Finite Element Method (FEM) models, studying low-frequency phenomena. This method includes making computer models that are adjusted and tested to be as close to real things as possible. Pictures below show how it moves in real life and in our computer model. We can tweak the computer model to match the real thing by making some changes. In one test, the computer model was off by only 3% for a certain movement at 132 times per second and 5% for another movement at 186 times per second. But remember, how well the computer model matches the real thing depends on how accurate the details are, like the applied materials and the set of limits that we use.

Signal processing of the measured data also involves the application of techniques such as spectral analysis and other methodologies to identify primary frequencies and potential sources. Exploring correlations between low-frequency noise and variables such as vehicle speed, engine RPM, and suspension characteristics becomes feasible through this approach. The FEM study not only provides profound insights into car vibroacoustic behavior but also plays a pivotal role in optimizing noise and vibration levels.

In the present study KFB team conducted acoustic measurements on the dynamometer test bench to characterize the low frequency noise. Then, we measured car body surface vibrations using the 3D-laser vibrometer on the vehicle to assess the impact of low-frequency excitation for selected operating conditions.

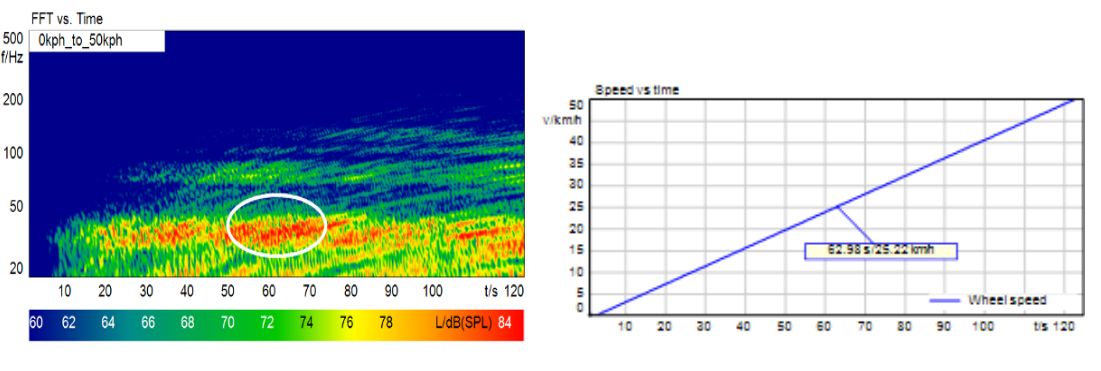

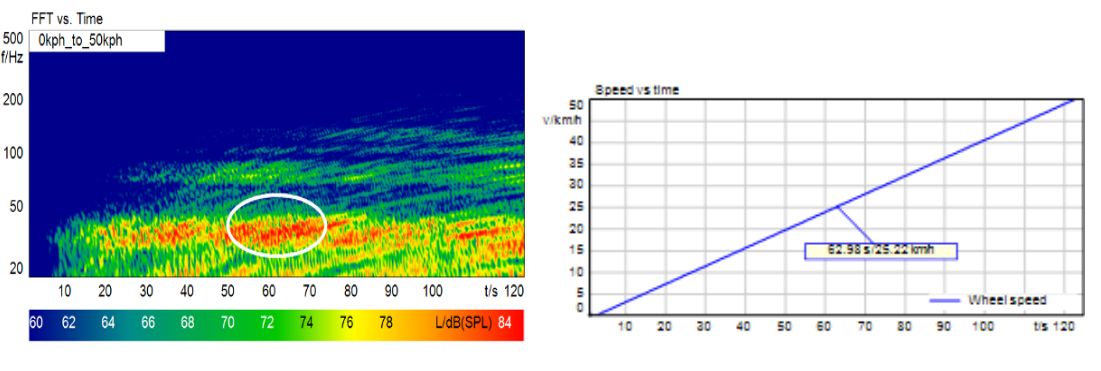

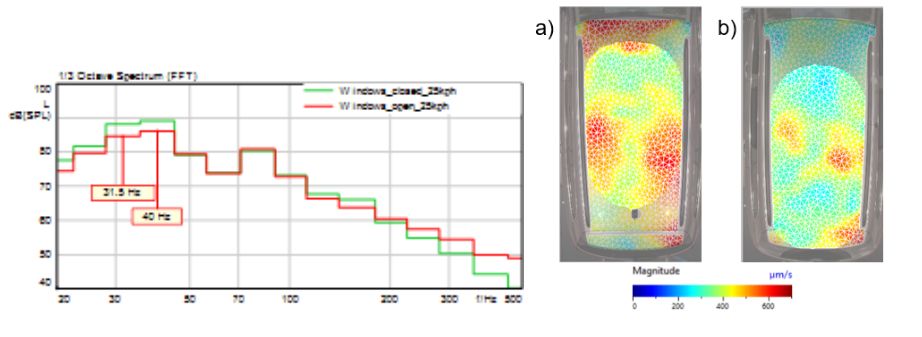

The acoustic study revealed that dominating frequencies are located around 40 Hz & 80 Hz. Those frequencies were responsible for the significant increase of sound pressure level inside the cabin. 25 km/h was selected as the car speed with the highest amplitude for those frequency bands.

3D-laser vibrometer results

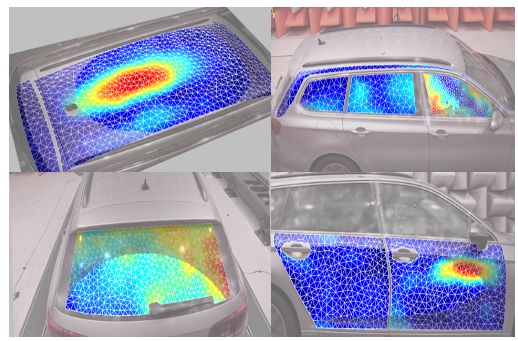

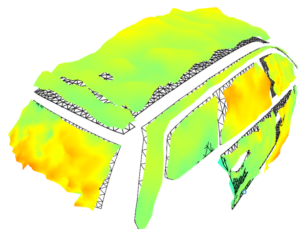

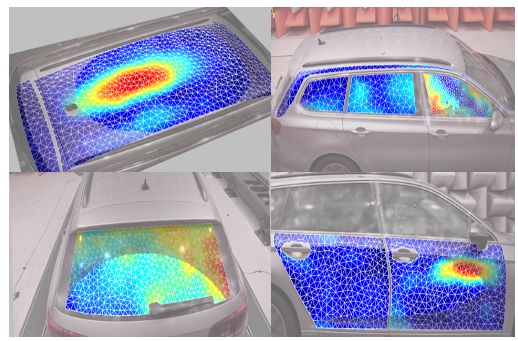

Vibration scanning was performed at 25 km/h car speed. Main cabin elements related to the car interior were scanned as shown in Figure below (roof, side windows, back window, side doors).

For considered frequency bands (40 Hz and 80 Hz) frequencies associated with the highest velocity magnitude were selected to present the form of vibrations (Figure below).

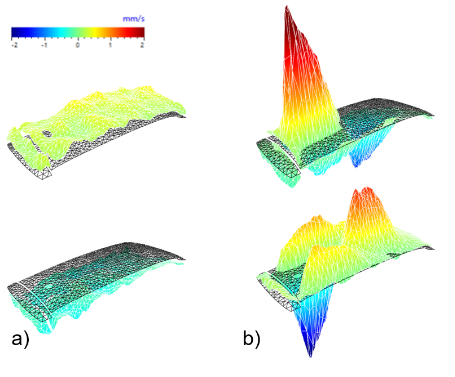

Based on the measurements it can be found that at 81 Hz the structural mode of the roof can be easily recognized. But for 36 Hz the whole roof surface vibrates in phase (Figure above ). For deeper understanding of this phenomena, a whole car cabin behaviour at this frequency vibration is presented on the 3D model (Figure Below). It can be seen from the figure below that each cabin element exhibits the same pumping motion. This vibration pattern can be associated with a global mode of the cabin.

Open and Closed window acoustic study

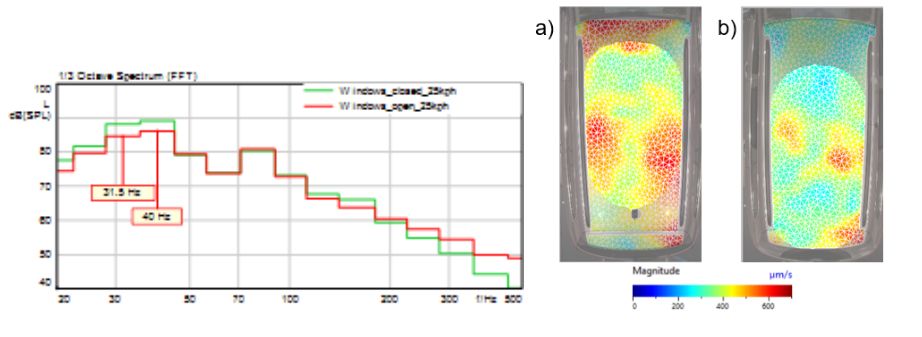

To find out the basic nature of the identified global mode at 36 Hz (Figure below) additional measurements with open window were performed.). The goal was to confirm the air cavity’s role in the mass-spring system with car cabin structure. The role of the acoustic cavity in the vibroacoustic response was also studied by others before.

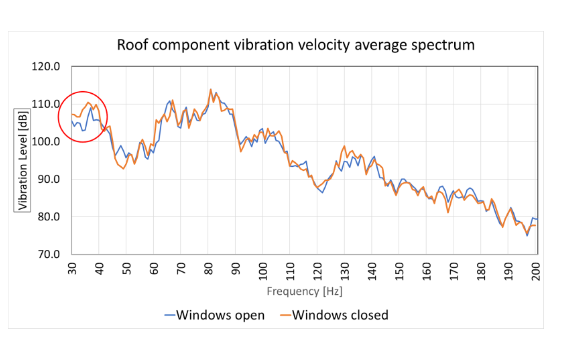

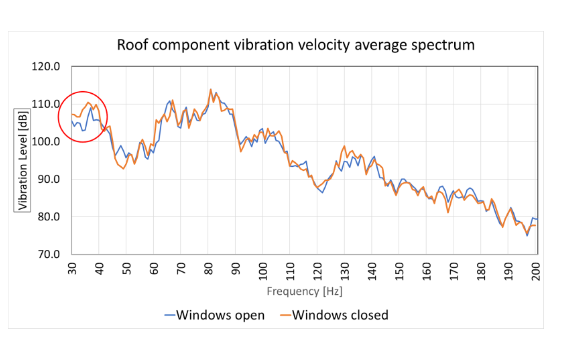

Measurements show that opening windows causes a significant sound level drop and vibration magnitude drop (Figure below) at the 40 Hz frequency band.

Figure below shows the difference in rooftop vibration velocity average spectrum with all windows closed and open. The biggest difference can be noticed in the mentioned 40 Hz frequency. This suggests that indeed the stiffness of air filling the cabin plays an essential role in forming this global mode.

Summary

In summary, this paper explores the intricate vibroacoustic behaviour of real-world car behaviour, specifically on low speeds and the conspicuous boom noise experienced during rough road drives or encounters with obstacles. Employing a tandem approach with an acoustic dynamometer and a 3D laser vibrometer facilitates comprehensive vibration measurements across the entire car body within identical operating conditions. Consequently, this approach unveils global modes that wield considerable influence over the noise experienced in the passenger cabin, particularly at lower frequencies, contributing to the perceived booming noise.

These global modes can be attributed to either the overall structural assembly of the car or the coupling of the structural assembly with the acoustic system inside the cabin. In the latter scenario, the car undergoes the well-recognized mass-spring resonance, where the air inside the cabin assumes the role of a spring, introducing stiffness. This phenomenon remains elusive when measuring individual car parts in isolation, underscoring the clear advantage of integrating the 3D laser vibrometer and acoustic dynamometer. This combination allows for a holistic scan of the entire car’s vibrations without the need to dissect the car structure during simulated driving conditions. Conversely, when issues arise at higher frequencies, the identification of local modes in individual parts becomes more accessible through the analysis of measured mode shapes.

The insights gleaned from this advanced dynamometer test facility offer an expanded understanding of vibroacoustic effects on cars. This newfound knowledge empowers vehicle manufacturers to pinpoint areas for potential enhancement in design and performance, paving the way for more effective noise reduction strategies and overall refinement of the vehicle. While strides have been made in the automotive industry, particularly in crafting lighter car body parts with optimized structures and minimizing engine noise, the challenge persists in addressing the low-frequency behaviour of car cabins, presenting an ongoing frontier for researchers and engineers alike.