AI noise recognition system

Industry

Industry, Cities, Airports

Scope of work

AI technology

Noise detection

Noise recognition

Acoustic monitoring

Have you ever noticed how acousticians, architects and engineers often talk about the environment? Well, it’s because they want to point out that most of the time there are a number of many different factors playing their role in a particular field, let’s say acoustics. Our acoustic analysis can give much more than just vague quantitative big picture. Here is how we deliver a detailed qualitative set of data using AI:

We recognize the problem

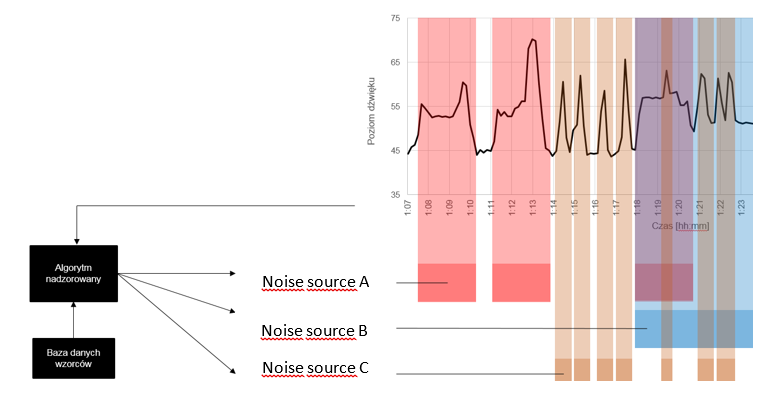

There are plenty of different sources of noise, often found outdoors and indoors, in industrial acoustics. Not only that, the resultant noise from multiple sources is often time-varying (both in terms of noise level and spectrum). An example of the noise level waveform is shown in Figure 1.

Figure 1.

Excessive noise and vibrations is a growing problem in professional environments and working areas like industry halls. This is why this matter is put under regulations that address this kind of issue. Companies are legally obliged to comply with recommendations and requirements defined in these regulations. The same thing goes to the noise pollution introduced into the external environment (e.g., impacts on residential areas located near industrial facilities)]. Most of those documents set some limits (permissible level, boundaries) on a number of acoustic indicators to be monitored if noise associated with a given control point is not excessive. Those indicators often take into account human hearing characteristics by imposing psychoacoustic corrections on measured quantities.

These acoustics indicators are:

- Weighted equivalent sound pressure level,

- Weighted peak sound pressure level,

- Weighted maximum sound pressure level.

We assess the situation

In practice, it comes down to identifying the acoustic events that make up the total noise in a given area. In order to effectively react to them, one must find answers to the following set of questions:

- Q1: What caused the vibroacoustic threat?

- Q2: When did it happen?

- Q3: Where did it happen?

The event identification consists in linking individual acoustic events (occurring in specific time periods) with the specified classes (Figure 2).

Performing such a classification manually is very time-consuming, inaccurate and prone to human error.

Figure 2.

We let the AI deal with the noise

To improve this process money and time wise, KFB Acoustics is currently running a project called “System for monitoring and identification of vibroacoustic threats”.

The system consists of a grid of sensors (microphones or intensity probes) distributed over the analyzed area and a central data analysis module (MCAD).

The MCAD is a programmatic implementation of all the algorithms discussed in this paper: supervised DNN (Deep Neural Network), unsupervised clustering algorithm (DBSCAN) and deterministic DSP (determination of tonality, impulsivity, spectral characteristics and direction of wave arrival).

Thanks to these solutions, we can now look at three aforementioned questions:

- Q1 can be answered based on labels obtained from DNN. Though, identification of some specific signals could be done only with a very low probability. Therefore, inclusion of tonality information, impulsivity, direction of wave arrival and spectral characteristics can significantly enrich the obtained data and help to identify the problematic sound source based only on those deterministic characteristics. In general, having multiple independent analysis tools can infer more about the phenomena under study.

- Answer to Q2 is always obtained, because the system is working in real time and is assigning time labels to each identified event.

- Q3 is answered based on localization algorithms.

Summary

Thanks to artificial intelligence algorithms, the System for monitoring and identification of vibroacoustic threats will essentially help to make a big leap into the next level of acoustic analysis, by doing the following:

- Automatically identifying acoustic events in real time and informing on an ongoing basis about identified events,

- Indicating the approximate location of the events,

- Displaying the exact timing of acoustic events.

This is a significant advantage compared to other solutions, such as microphone arrays and intensity probes, where it is possible to determine only the direction of the arrival of the acoustic wave.

Moreover, the available alternatives do not offer automatic event identification and are therefore incomplete alternatives. The implementation of the system will be based on a network of intelligent sensors, able to communicate not only with the central unit, but also with each other.

Examples of application would include a variety of instances, mainly: environmental acoustics, noise in industrial plants, monitoring the operation of machines and devices.